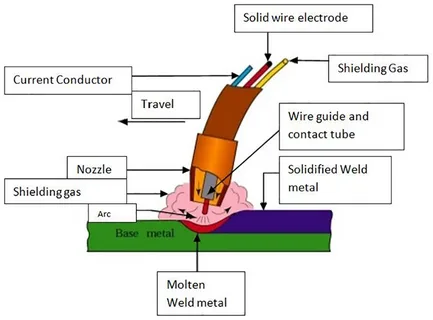

Manual Metal Arc Welding (MMAW), also known as Stick Welding, is one of the most commonly used welding techniques across various industries. It involves using a consumable electrode coated with flux to create a weld. It’s a versatile process that can be used on many materials, making it suitable for a wide range of applications. In this article, we will explore which materials can be welded using Manual Metal Arc Welding (MMAW) and why this method is chosen for different welding jobs.

Note : Ready to master Manual Metal Arc Welding and take your skills to the next level? Whether you’re a beginner or an experienced welder, understanding the materials you can weld with MMAW is key to achieving strong, reliable results. Start your next project today and explore the versatility of Manual Metal Arc Welding! Need help or want to learn more? Contact us now and let’s get welding

Introduction to Manual Metal Arc Welding (MMAW)

Manual Metal Arc Welding is a welding process that involves an electric current to melt the metal at the welding site, using a stick-like electrode coated in flux. The flux helps to protect the weld area from contaminants in the air, ensuring a clean and strong weld.

MMAW is often preferred for its simplicity, affordability, and ability to be used on various materials. Whether it’s a small DIY project or a large industrial application, the flexibility of MMAW allows it to be used on many types of metals and alloys.

What Materials Can Be Welded Using MMAW?

1. Mild Steel

What Makes Mild Steel Ideal for MMAW?

Mild steel is one of the most commonly welded materials using Manual Metal Arc Welding. It is inexpensive, easy to handle, and highly versatile. Mild steel is made up of a low amount of carbon, which makes it relatively soft and easy to weld. The properties of mild steel make it perfect for a wide range of applications, from car frames to building structures.

Types of Mild Steel Welded with MMAW

There are various grades and types of mild steel, such as:

- Low-carbon steel: Used in applications that require high ductility, like automotive bodywork.

- High-carbon steel: Used for applications needing strength and wear resistance, such as cutting tools.

MMAW is particularly effective for welding low-carbon steel, which is commonly used in construction, automotive, and general manufacturing industries.

2. Stainless Steel

Can You Weld Stainless Steel Using MMAW?

Yes, stainless steel is another material that can be welded using Manual Metal Arc Welding. Stainless steel contains a high amount of chromium, making it resistant to corrosion and staining. While it can be a little more challenging to weld compared to mild steel, it is still a popular choice for MMAW.

What to Keep in Mind When Welding Stainless Steel with MMAW

When welding stainless steel, it’s important to choose the right electrode. Stainless steel electrodes are specially designed to avoid contamination and provide a clean weld. In addition, proper heat control is essential to prevent the material from warping or becoming brittle.

3. Aluminum

Can Aluminum Be Welded Using MMAW?

While aluminum can technically be welded using MMAW, it is generally more challenging than other metals. Aluminum is lightweight and has high thermal conductivity, meaning it disperses heat very quickly. This can make it harder to maintain a steady weld pool.

How to Weld Aluminum with MMAW?

To weld aluminum effectively with MMAW, it’s important to use a special aluminum electrode and adjust the heat settings carefully. Additionally, aluminum often needs to be cleaned properly to remove oxide layers, which can interfere with the welding process.

Although it’s more difficult, MMAW is still used for aluminum welding in situations where other welding techniques, like TIG or MIG welding, may not be feasible.

4. Cast Iron

Can You Weld Cast Iron Using MMAW?

Cast iron can be welded with MMAW, but it requires extra attention. Cast iron is a brittle material and has a high carbon content, which makes it prone to cracking. To weld cast iron successfully, the welder needs to use the right filler metal and maintain proper heat control throughout the process.

How to Weld Cast Iron with MMAW?

When welding cast iron, it’s essential to use a specialized electrode designed for cast iron welding. Preheating the metal can also help reduce the risk of cracking. After welding, it’s necessary to let the metal cool slowly to prevent any further damage.

5. Copper and Copper Alloys

Can Copper Be Welded with MMAW?

Copper is another metal that can be welded with MMAW, although it requires special attention. Copper is a highly conductive metal, meaning it doesn’t hold heat as well as other metals. As a result, welders must be mindful of their heat settings to ensure a solid weld.

Welding Copper with MMAW

When welding copper, the key is to use the right electrodes, typically made from copper or copper alloys. It is important to maintain a steady heat level to avoid overheating, which can lead to porosity and weak welds.

Copper alloys, like bronze and brass, can also be welded using MMAW. However, each alloy may require specific electrodes for the best results.

6. High-Strength Low-Alloy Steel

What Is High-Strength Low-Alloy Steel?

High-strength low-alloy (HSLA) steel is a type of steel that contains small amounts of alloying elements like manganese, chromium, and vanadium. These alloys make the steel stronger and more resistant to corrosion, making it suitable for applications like bridges, pipelines, and pressure vessels.

Welding HSLA Steel with MMAW

MMAW is ideal for welding HSLA steel because the process can provide a high-quality weld with excellent strength. When welding HSLA steel, it’s important to choose the correct electrodes that match the material’s strength and to control heat input to prevent weakening the steel.

7. Tool Steels

Can Tool Steels Be Welded Using MMAW?

Tool steels, which are designed for manufacturing tools and dies, can also be welded using MMAW. These steels have high carbon content and are alloyed with elements like tungsten and molybdenum for extra hardness. Welding tool steels can be tricky because of their hardness, but it is possible with the right preparation.

Welding Tool Steels with MMAW

Tool steels require specific care during welding. A preheat treatment may be needed, and the right filler metal should be selected to ensure that the weld has similar hardness and strength to the base material. Post-weld heat treatment may also be necessary to restore the hardness of the tool steel after welding.

8. Nickel and Nickel Alloys

Can Nickel Be Welded with MMAW?

Yes, nickel and its alloys are commonly welded using MMAW. Nickel is a corrosion-resistant metal, often used in harsh environments like chemical plants and marine applications. It is highly ductile and can be welded without much difficulty, although it does require specific filler materials.

Welding Nickel with MMAW

When welding nickel alloys, it’s important to use electrodes that are compatible with the specific type of nickel being welded. Proper heat control is essential to prevent the metal from becoming too brittle.

9. Titanium and Titanium Alloys

Is It Possible to Weld Titanium Using MMAW?

Welding titanium with MMAW is possible, but it’s not as common as using other welding methods. Titanium is highly reactive to oxygen, nitrogen, and hydrogen, so it requires a high level of control during the welding process.

Welding Titanium with MMAW

When welding titanium, the welder must ensure that the material is free from contaminants. This may involve purging the weld area with inert gas to keep the titanium from reacting with the atmosphere. Proper heat settings and specialized electrodes are necessary for welding titanium successfully.

10. Magnesium and Magnesium Alloys

Can Magnesium Be Welded with MMAW?

Magnesium, like aluminum, can be welded using MMAW, but it requires specific attention. Magnesium is highly flammable when exposed to heat, so the welding process must be controlled carefully.

Welding Magnesium with MMAW

To weld magnesium with MMAW, the welder must use the right electrodes and keep the temperature controlled. Magnesium also needs to be cleaned properly before welding to avoid contamination, which could lead to weak welds.

Conclusion: Choosing the Right Material for MMAW

Manual Metal Arc Welding (MMAW) is a highly flexible and effective welding technique that can be used on a variety of materials. Whether you’re working with mild steel, stainless steel, or even more challenging materials like titanium or magnesium, MMAW offers a reliable and cost-effective solution. However, the key to successful welding is choosing the right materials and understanding how to handle them properly.

Different materials require different electrodes, filler metals, and heat settings. The welder’s skill and the preparation of the materials also play a crucial role in achieving a strong, durable weld. For best results, it’s important to know the properties of the materials you are working with and to select the right tools and techniques for each.

If you are looking to weld a specific material, make sure to consult experts and use the appropriate equipment to get the best possible results.

So, which material will you weld next using MMAW? Take your time to consider the material, and with the right preparation and knowledge, you’ll be able to complete your project successfully

For more insightful articles related to this topic, feel free to visit : viewsparrow.com