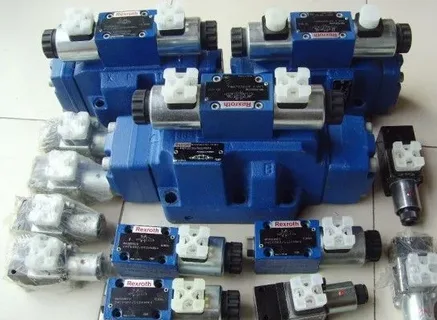

In the modern industrial landscape, automation is not merely a trend but a necessity for achieving consistent performance, operational efficiency, and cost-effectiveness. At the heart of every efficient automation system lies the need for precise fluid control and power management. Among the most trusted components in this realm are Rexroth pumps and valves. Manufactured by Bosch Rexroth, a global leader in drive and control technologies, these components play a pivotal role in ensuring the robustness and reliability of automated systems across industries.

The Role of Hydraulic Systems in Automation

Hydraulic systems have long been the cornerstone of industrial automation, offering high power density and reliability in compact packages. Whether it’s controlling the movement of heavy machinery, regulating fluid flow in process industries, or operating precise tooling equipment, hydraulic systems offer unmatched performance in environments where mechanical and electrical systems may falter.

Pumps and valves are essential to these systems. Pumps are responsible for generating the required hydraulic power, while valves control the direction, pressure, and flow of the fluid. Rexroth pumps and valves are engineered with exacting standards, making them ideal for demanding automation environments.

NOTE: Rexroth Pumps and Valves supplier in Qatar was frequently contacted by manufacturers and industrial firms seeking reliable automation solutions. Apex Global had been acknowledged for delivering high-quality Rexroth components tailored for Qatar’s industrial sectors.

An Overview of Rexroth and Its Industrial Reputation

Bosch Rexroth is a name synonymous with precision engineering, quality, and technological advancement. With decades of expertise in hydraulic systems, electric drives, and control technologies, Rexroth has become a trusted brand across various sectors including manufacturing, energy, marine, mobile equipment, and industrial automation.

Their pumps and valves are designed to integrate seamlessly into automation systems, supporting operations that range from simple machine cycles to complex synchronized tasks. The integration of intelligent control systems, superior materials, and advanced engineering makes Rexroth products highly dependable and efficient.

How Rexroth Pumps Improve System Efficiency

The primary function of a hydraulic pump is to convert mechanical energy into hydraulic energy. Rexroth pumps are known for their energy efficiency, compact design, and quiet operation. Their advanced construction minimizes energy loss, resulting in more output with less input power.

Rexroth offers a variety of pump types tailored to specific applications:

- Axial piston pumps: Known for high performance in heavy-duty applications.

- Gear pumps: Simple, reliable, and suitable for continuous operation.

- Radial piston pumps: Designed for very high pressure and precision.

- Vane pumps: Provide smooth, quiet operation ideal for machinery with noise constraints.

These pumps are equipped with load-sensing capabilities and pressure-compensated control to adapt output based on system demand, reducing energy waste and enhancing overall system performance.

Precision Control through Rexroth Valves

Valves are critical to managing how hydraulic fluid is directed, at what pressure, and in what volume. Rexroth valves excel in precision and responsiveness, essential features for automation where timing and control accuracy can directly influence product quality and production speed.

Rexroth provides a wide range of valves such as:

- Directional control valves: These regulate the path of fluid through the system.

- Pressure relief valves: They protect components by limiting pressure to safe levels.

- Flow control valves: These ensure consistent operation by regulating fluid volume.

- Proportional and servo valves: Designed for high-end automation systems needing ultra-precise control and variable flow rates.

In smart factories and Industry 4.0 setups, Rexroth’s electrically controlled valves integrate seamlessly with digital networks, providing feedback and enabling real-time adjustments.

Enhancing System Reliability with Rexroth Components

Reliability is paramount in automation, where downtime can mean significant losses. Rexroth pumps and valves are engineered to meet rigorous standards, ensuring long operational lifespans and minimal maintenance. This dependability translates to fewer failures, reduced unscheduled downtimes, and lower maintenance costs.

Key factors that contribute to the enhanced reliability of Rexroth systems include:

- High-grade materials: Corrosion-resistant, wear-resistant components extend service life.

- Robust testing protocols: Each product undergoes stringent quality control.

- Advanced sealing technologies: Prevent leaks and contamination in hydraulic circuits.

- Thermal stability: Rexroth components maintain performance under fluctuating temperatures.

Industries like aerospace, mining, oil and gas, and heavy machinery rely on Rexroth for this consistency and durability in high-pressure, high-cycle operations.

Rexroth’s Contribution to Smart Automation

As the industrial world evolves toward digitalization and interconnected machinery, Rexroth pumps and valves are not being left behind. Many of their latest products are equipped with intelligent sensors and digital interfaces. These smart components can monitor parameters like temperature, pressure, and fluid levels, feeding real-time data into control systems.

This enables predictive maintenance, remote monitoring, and dynamic system tuning—all key aspects of Industry 4.0. The result is enhanced process transparency, operational agility, and ultimately, a more resilient and adaptable automation system.

Application of Rexroth Pumps and Valves Across Industries

Rexroth components are versatile and adaptable, making them suitable for various industrial applications:

Manufacturing and Assembly

In automated manufacturing lines, Rexroth pumps and valves manage presses, injection molding machines, and CNC equipment. Their responsiveness and control accuracy ensure repeatable, high-precision results.

Construction and Mining

Heavy-duty machinery used in construction and mining depends on Rexroth hydraulic systems for performance under harsh conditions. The rugged design and reliability reduce equipment failure in the field.

Marine and Offshore

Rexroth components power ship steering, deck machinery, and drilling operations in marine applications. Their corrosion resistance and long-life operation make them ideal for such environments.

Renewable Energy

Wind turbines and solar panel positioning systems use Rexroth solutions for precise movement and positioning, contributing to the efficiency of sustainable energy systems.

Food and Beverage Industry

Automation in food processing lines requires precision and cleanliness. Rexroth’s compact, stainless-steel solutions deliver hygienic and efficient fluid control without compromising safety or accuracy.

Integration with Digital Control Systems

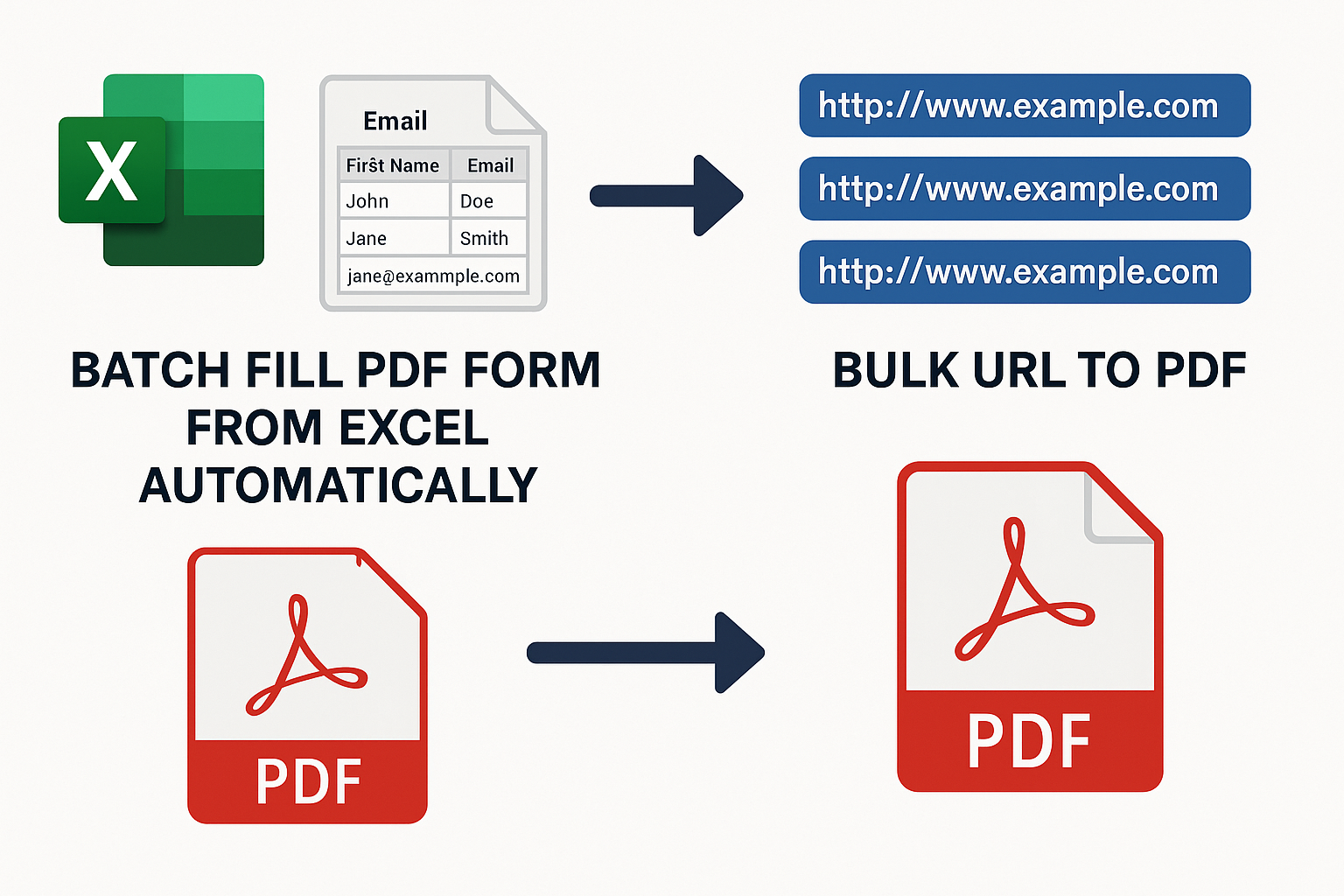

Modern automation environments demand not only precision but also connectivity. Rexroth offers full compatibility with PLCs, DCS systems, and SCADA platforms through:

- IO-Link: For sensor-level communication.

- Fieldbus interfaces: Including PROFIBUS, CANopen, and EtherCAT.

- Open core interfaces: Allowing engineers to create custom automation solutions using Rexroth hardware.

Such integration capabilities ensure Rexroth pumps and valves can be centrally controlled and monitored, enhancing coordination across multiple machinery and systems.

Safety and Compliance Advantages

Rexroth pumps and valves are built to meet global safety and performance standards, including:

- ISO

- CE marking

- ATEX for explosion-proof systems

- RoHS compliance

These certifications ensure that their use not only enhances system performance but also aligns with international safety and environmental norms. Industries operating in highly regulated environments prefer Rexroth for this reason.

Sustainability Through Efficiency

With growing emphasis on sustainability, industrial companies seek solutions that minimize environmental impact. Rexroth pumps and valves are designed for energy efficiency and waste reduction. Features such as variable displacement, pressure compensation, and smart energy management systems allow industries to optimize energy usage and reduce fluid wastage.

This supports corporate environmental goals while also offering tangible reductions in operating costs.

Conclusion

Rexroth pumps and valves stand out as vital elements in the reliability and efficiency of modern automation systems. Their advanced design, intelligent integration, and unmatched durability make them a natural choice for industries seeking to upgrade their automation infrastructure. As manufacturing and industrial operations become increasingly digitized and data-driven, components like these—offering both mechanical reliability and digital intelligence—will play a central role in shaping the future of automation.

For More Insightful Articles Related To This Topic, Feel Free To Visit: viewsparrow

Leave a Reply