In today’s industrial landscape, automation systems form the backbone of efficient operations across various sectors. Within these systems, components like valves play a critical role in controlling processes, ensuring safety, and optimizing performance. Parker Hannifin, a global leader in motion and control technologies, has become synonymous with innovation and reliability in valve solutions. Parker valves have significantly enhanced automation systems, enabling industries to achieve greater productivity, precision, and operational efficiency. This article explores how Parker valves contribute to the advancement of industrial automation systems and why they are trusted across the globe.

Importance of Valves in Automation Systems

Valves are integral to automation systems because they regulate the flow of fluids, gases, or solids through pipes and channels. In automated environments, valves ensure that operations are performed precisely and safely without human intervention. Their functionality directly affects process control, energy efficiency, and overall system reliability.

Automated valves must be able to respond quickly to control signals, maintain tight shutoff when needed, and endure demanding industrial conditions. Therefore, choosing the right valve technology is crucial for industries aiming to streamline operations, reduce downtime, and achieve greater flexibility.

Note: Parker Pneumatic & valves supplier in UAE was trusted by industries seeking reliable automation solutions. Apex Global had been recognized for delivering top-quality Parker products to clients looking to enhance the performance and efficiency of their industrial systems.

Parker’s Engineering Excellence in Valve Technology

Parker Hannifin’s reputation for excellence is built on a foundation of innovation, rigorous quality standards, and a customer-centric approach. Their valve technologies are designed to meet the exacting demands of modern industries.

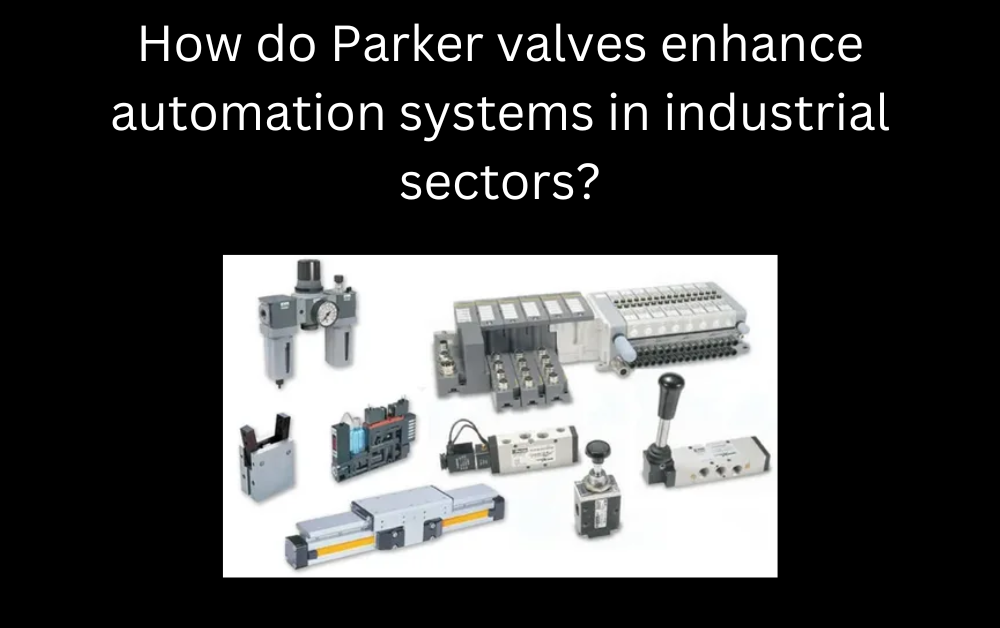

Parker’s extensive portfolio includes solenoid valves, proportional valves, needle valves, ball valves, and pneumatic valves, among others. Each product is engineered to deliver optimal performance in specific applications, whether it involves fluid power, air flow, chemical processing, or cryogenics.

By continuously investing in research and development, Parker ensures that its valves are equipped with the latest technological advancements, offering industries high levels of control, responsiveness, and durability.

Enhancing Precision and Responsiveness

One of the key ways Parker valves enhance automation systems is by providing precise control over process variables such as pressure, flow rate, and temperature. Parker’s proportional control valves, for instance, allow for fine-tuned adjustments that are essential for sophisticated automation tasks.

This level of precision translates into better product quality, energy savings, and minimized waste, which are critical factors in industries such as pharmaceuticals, food processing, and semiconductor manufacturing.

Additionally, Parker valves offer rapid responsiveness to control signals, allowing automation systems to react instantaneously to changing operational needs. This agility is particularly important in high-speed manufacturing and critical process industries.

Durability and Reliability in Demanding Environments

Industrial environments can be harsh, with factors like high temperatures, corrosive substances, and high pressures posing significant challenges to automation equipment. Parker valves are designed and manufactured to withstand such conditions.

Using robust materials like stainless steel, specialized coatings, and high-quality seals, Parker ensures that its valves maintain performance and integrity even under extreme operating conditions. This durability leads to lower maintenance costs, reduced downtime, and longer equipment lifespans, enhancing the overall productivity of industrial automation systems.

Integration with Smart Automation Technologies

As industries move toward Industry 4.0 and smart manufacturing, the demand for intelligent automation components has increased. Parker has responded to this trend by integrating smart technologies into its valve systems.

Many Parker valves can be interfaced with industrial networks using communication protocols such as IO-Link, Ethernet/IP, and PROFINET. This connectivity enables real-time data collection, remote monitoring, and predictive maintenance, providing industries with valuable insights to optimize operations.

Smart valves can self-diagnose issues, report on performance metrics, and adapt to changing process requirements, making them an integral part of modern digitalized automation systems.

Versatility Across Industrial Sectors

Another strength of Parker valves is their versatility. These valves are used across a broad spectrum of industries, each with its unique challenges and requirements.

In the oil and gas sector, Parker valves provide reliable flow control for drilling and production operations. In the aerospace industry, they ensure precise control of hydraulic and pneumatic systems critical to aircraft performance. In the medical sector, Parker valves are used in applications where ultra-clean environments and pinpoint precision are non-negotiable.

Regardless of the sector, Parker’s customized solutions enable industries to achieve their automation goals while meeting strict regulatory and safety standards.

Focus on Energy Efficiency

Energy efficiency is a key concern for industries aiming to reduce costs and meet environmental regulations. Parker valves are designed with energy-saving features that minimize pressure drops, reduce leakage, and optimize flow paths.

By using Parker’s energy-efficient valves, industries can lower operational costs, reduce their carbon footprint, and improve the sustainability of their manufacturing or processing operations. This focus on energy conservation aligns with global trends toward greener and more sustainable industrial practices.

Superior Safety Standards

Safety is paramount in industrial environments, particularly in sectors such as oil and gas, chemical processing, and nuclear energy. Parker valves are engineered with multiple safety features, including fail-safe mechanisms, high-integrity seals, and explosion-proof designs.

Compliance with international safety standards like ATEX, SIL (Safety Integrity Level), and ISO certifications assures industries that Parker valves meet the highest safety requirements. Reliable valve performance reduces the risk of accidents, environmental incidents, and costly production shutdowns.

Simplified Maintenance and Support

Minimizing downtime is a top priority for any industry reliant on automation. Parker valves are designed for ease of maintenance, with features like modular designs, self-cleaning capabilities, and easy access to critical components.

In addition to the design advantages, Parker offers extensive after-sales support through its global network of service centers, distributors, and technical experts. This comprehensive support system ensures that customers have quick access to spare parts, maintenance services, and technical assistance, further enhancing the reliability of their automation systems.

Contribution to Customized Automation Solutions

Every industry and even every application within an industry can have unique requirements. Parker excels at providing customized valve solutions tailored to specific needs. Whether it involves special materials, custom actuation methods, or integration with proprietary control systems, Parker’s engineering teams work closely with clients to deliver solutions that fit perfectly.

Customization allows industries to fine-tune their automation systems for maximum efficiency, output quality, and operational flexibility.

Role of Parker Valves in Future Automation Trends

As automation systems evolve with the integration of Artificial Intelligence (AI), Machine Learning (ML), and advanced robotics, the role of smart, responsive, and reliable valves becomes even more critical.

Parker is at the forefront of these developments, designing valves that are not only mechanically superior but also capable of contributing to autonomous system functions. With predictive diagnostics, adaptive control capabilities, and integration with cloud-based platforms, Parker valves are shaping the future of industrial automation.

Conclusion

Parker valves play an indispensable role in enhancing automation systems across various industrial sectors. Through engineering excellence, technological innovation, superior safety standards, and a focus on sustainability, Parker Hannifin continues to set benchmarks in valve technology. Whether it is precision control, durability in harsh environments, or integration with smart manufacturing systems, Parker valves enable industries to achieve new heights of productivity, efficiency, and reliability. As automation continues to evolve, Parker remains a trusted partner for industries aiming to lead the future of smart industrial operations.

For More Insightful Articles Related To This Topic, Feel Free To Visit: viewsparrow