The journey a product takes from the factory floor to the customer’s doorstep is fraught with potential hazards. Shocks, vibrations, and impacts during transit can lead to costly damage and dissatisfied customers. Custom EPE Foam Packaging emerges as a crucial solution, playing an indispensable role in ensuring damage-free delivery for a wide range of goods. From delicate electronics to fragile glassware, EPE Foam Packaging provides the necessary protection to safeguard products throughout their journey. This comprehensive guide explores the vital role of EPE foam in creating secure transit, highlighting its benefits and applications for businesses in Mumbai, Navi Mumbai, Thane, Panvel, the USA, UK, and Australia.

The Risky Road: Understanding Transit Hazards

Products encounter numerous challenges during their journey from manufacturing to the final destination. These hazards can compromise product integrity and lead to significant financial losses for businesses. Effective packaging acts as a robust barrier against these risks.

Common Transit Hazards:

- Impact Forces: Sudden drops or collisions during loading, unloading, and transportation.

- Vibrations: Continuous shaking and movement during road, rail, air, and sea travel.

- Compression: Pressure exerted by stacking other packages on top.

- Abrasion: Rubbing and friction against other items or the packaging itself.

- Punctures: Sharp objects piercing the packaging.

- Temperature Fluctuations: Extreme heat or cold potentially damaging sensitive goods.

- Humidity and Moisture: Exposure to damp conditions leading to corrosion or weakening of packaging.

Mitigating these risks requires careful consideration of packaging materials and design. Custom EPE Foam Packaging offers a powerful tool in this endeavor.

EPE Foam: Engineered for Protection Across the Supply Chain

Expanded Polyethylene (EPE) foam is a closed-cell, non-crosslinked foam prized for its exceptional cushioning and shock-absorbing properties. Its unique cellular structure provides consistent protection, unlike materials that rely on air pockets. This makes EPE Foam Packaging for electronics, EPE Foam Packaging for glassware, and EPE Foam Packaging for fragile items a reliable choice for businesses aiming for damage-free delivery.

Key Protective Attributes of EPE Foam:

- Outstanding Shock Absorption: Effectively dissipates impact energy, minimizing damage from drops and bumps.

- Consistent Cushioning: Maintains protective qualities even under compression.

- Non-Abrasive Nature: Safeguards delicate surfaces from scratches and scuffs.

- Water Resistance: Offers a barrier against moisture ingress.

- Lightweight Design: Adds minimal weight to shipments, potentially reducing shipping costs.

- Customizability: Easily cut and shaped to create tailored protective solutions.

The closed-cell structure ensures that EPE foam provides reliable protection throughout the distribution process, from the factory in Navi Mumbai to a customer in New York City.

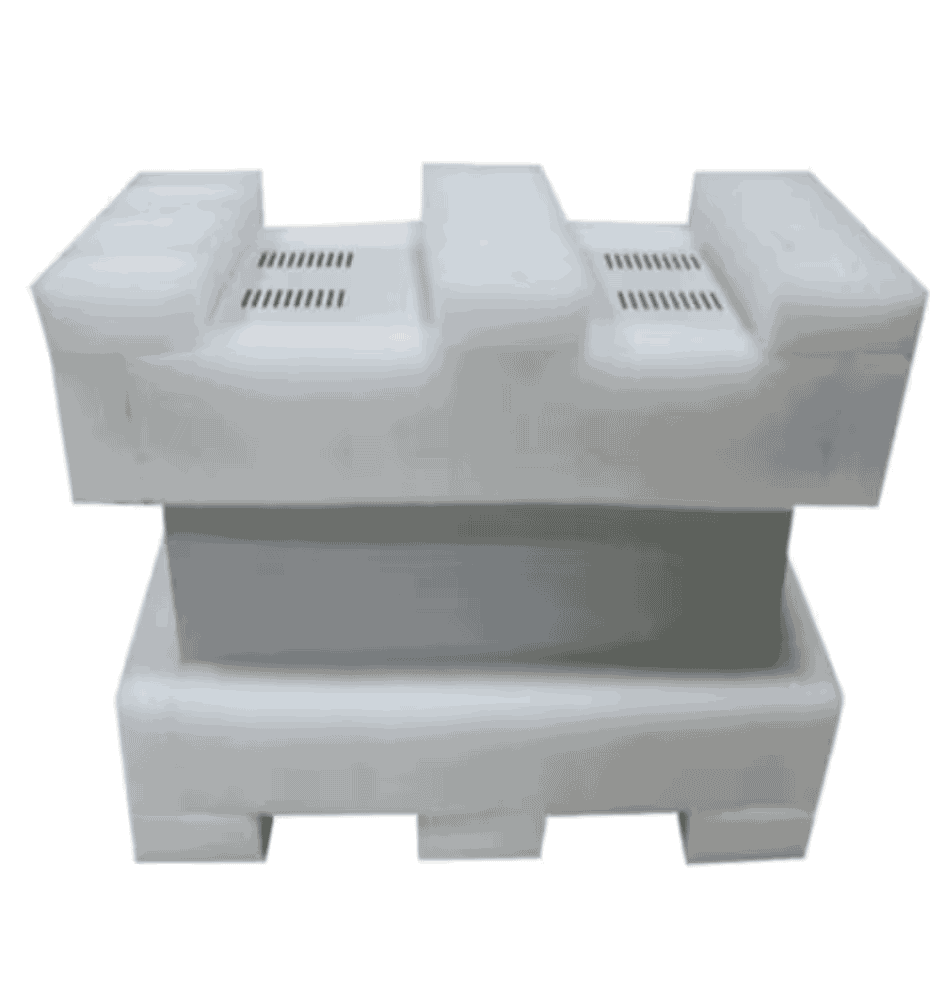

The Power of Customization: EPE Foam Inserts for Ultimate Security

While EPE foam sheets and rolls offer basic protection, Custom EPE Foam Packaging often involves the creation of precisely designed inserts. These inserts are meticulously shaped to cradle individual products, providing a snug and secure fit that minimizes movement during transit.

Benefits of Custom EPE Foam Inserts for Damage Prevention:

- Immobilization: Custom-fit cavities hold products firmly, preventing internal movement that can lead to damage from shocks and vibrations during transport, whether across Thane or overseas to the UK.

- Example: Sensitive electronic components packaged in EPE Foam Packaging for electronics with custom inserts are far less likely to suffer damage during air freight from Mumbai to Los Angeles.

- Targeted Shock Absorption: Inserts can be designed with specific thicknesses and densities of EPE foam in critical impact zones, providing enhanced protection where it’s needed most for EPE Foam Packaging for fragile items.

- Example: Fragile scientific instruments shipped from a manufacturer in Panvel to a research facility in Australia are protected by custom EPE foam inserts that cushion delicate protrusions and sensitive areas.

- Surface Protection: The smooth, non-abrasive surface of EPE foam ensures that delicate finishes on products like glassware and polished metal are protected from scratches and scuffs during handling. EPE Foam Packaging for glassware with custom dividers prevents item-on-item contact.

- Example: Delicate crystalware being shipped from a supplier in the UK to a retailer in Sydney arrives in pristine condition thanks to Custom EPE Foam Packaging with precisely molded EPE foam cavities.

- Optimized Space Utilization: Custom inserts maximize the use of packaging space, reducing the need for excessive void fill and creating a more stable and secure internal environment for the product, potentially lowering shipping costs for businesses in Mumbai.

- Example: By using Custom EPE Foam Packaging tailored to the exact dimensions of their products, businesses in Navi Mumbai can reduce their packaging footprint and shipping expenses.

Diverse Applications: Protecting Products Across Industries

The versatility of Custom EPE Foam Packaging makes it an indispensable solution for a wide range of industries shipping goods to diverse locations, including Mumbai, Navi Mumbai, Thane, Panvel, the USA, UK, and Australia:

- Electronics: Safeguarding sensitive electronic components, assemblies, and finished devices from electrostatic discharge (ESD-safe options), shock, and vibration. EPE Foam Packaging for electronics is vital for manufacturers and distributors globally.

- Glassware and Ceramics: Providing secure cushioning and separation for fragile bottles, tableware, and decorative items, preventing breakage during transit. EPE Foam Packaging for glassware is crucial for businesses dealing with delicate items.

- Fragile Instruments: Protecting sensitive medical devices, laboratory equipment, optical instruments, and artwork from damage during transportation. EPE Foam Packaging for fragile items ensures the integrity of valuable and delicate goods.

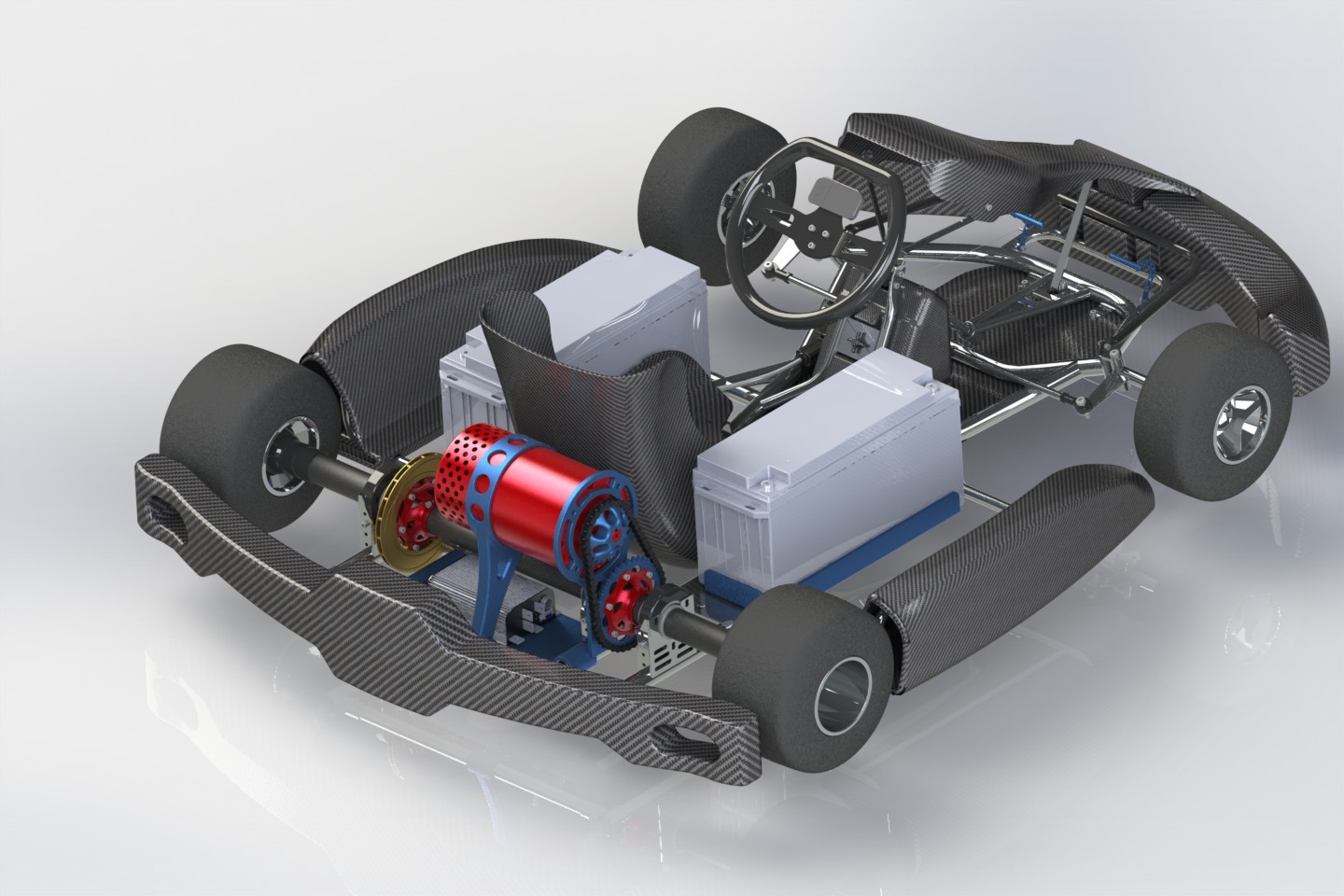

- Automotive Parts: Securing intricate and often heavy automotive components during shipping to assembly plants and repair shops.

- Consumer Goods: Providing protective packaging for a wide array of products, from cosmetics and personal care items to tools and hardware.

Top Cities in Target Markets:

- USA: New York City, Los Angeles, Chicago, Houston, Phoenix, Philadelphia, San Antonio, San Diego, Dallas, San Jose.

- UK: London, Birmingham, Manchester, Liverpool, Leeds, Glasgow, Sheffield, Edinburgh, Bristol, Belfast.

- Australia: Sydney, Melbourne, Brisbane, Perth, Adelaide, Gold Coast, Canberra, Newcastle, Sunshine Coast, Wollongong.

Businesses in these major urban centers, as well as the industrial hubs around Mumbai, rely on the consistent protection offered by Custom EPE Foam Packaging.

Designing for Damage Prevention: A Strategic Approach

Creating effective Custom EPE Foam Packaging requires a strategic design process focused on preventing damage:

- Product Vulnerability Assessment: Identifying the most fragile parts of the product and the types of stresses it is likely to encounter during transit.

- Shock and Vibration Analysis: Understanding the expected levels of shock and vibration based on the chosen transportation methods.

- Material Selection: Choosing the appropriate density and thickness of EPE foam to provide adequate cushioning and support for the product’s weight and fragility.

- Custom Insert Design: Creating precise cavities and support structures that immobilize the product and absorb impact forces. CAD/CAM technology ensures accuracy.

- Prototyping and Testing: Developing prototypes and conducting drop tests and vibration tests to evaluate the effectiveness of the packaging design.

- Ergonomic Considerations: Designing packaging that is easy for workers to handle and pack, reducing the risk of mishandling.

Experienced Custom EPE Foam Packaging suppliers in Mumbai, Navi Mumbai, Thane, and serving international markets can guide businesses through this design process to create optimal protective solutions.

The Economic Benefits of Damage-Free Delivery

Investing in effective packaging like Custom EPE Foam Packaging yields significant economic benefits beyond simply preventing product damage:

- Reduced Return Rates: Fewer damaged products mean fewer returns and refunds, saving businesses money and resources.

- Lower Replacement Costs: Minimizing damage directly reduces the cost of replacing damaged goods.

- Enhanced Customer Satisfaction: Receiving undamaged products leads to happier customers and stronger brand loyalty.

- Reduced Shipping Costs (Potentially): Optimized packaging can sometimes reduce the overall size and weight of shipments.

- Minimized Insurance Claims: Fewer damaged shipments translate to fewer insurance claims and lower premiums.

- Positive Brand Image: Consistent delivery of undamaged goods enhances the brand’s reputation for quality and reliability.

For businesses in competitive markets like the USA and UK, ensuring damage-free delivery is crucial for maintaining a positive brand image and customer trust.

EPE Foam – The Cornerstone of Secure Product Transit

In the complex world of global logistics, ensuring products arrive safely at their final destination is a critical imperative. Custom EPE Foam Packaging, with its tailored inserts and inherent protective qualities, stands as a cornerstone of secure product transit. From the factory floor in Navi Mumbai to the customer’s doorstep in Australia, EPE foam provides a reliable shield against the myriad hazards of the supply chain. By investing in EPE Foam Packaging for electronics, EPE Foam Packaging for glassware, and EPE Foam Packaging for fragile items, businesses in Mumbai, Navi Mumbai, Thane, Panvel, the USA, UK, and Australia can significantly reduce damage rates, enhance customer satisfaction, and ultimately protect their bottom line. The versatility and effectiveness of EPE foam make it an indispensable material for ensuring that products complete their journey safely and securely.

Best Searchable Keyword Variations

- Preventing shipping damage with custom foam inserts

- Best protective packaging for fragile goods transit

- EPE foam packaging solutions Mumbai suppliers

- Secure packaging for electronics during shipping

- Damage-free delivery with EPE foam UK

- Shock-resistant packaging for glassware Australia

- Benefits of custom EPE foam for product safety

- Cost-effective protective packaging for shipping

- Design custom EPE foam packaging for fragile items

- Top EPE foam packaging manufacturers near me

- 3 Ply Single Wall

- 5 Ply Double Wall

- 7 Ply Triple Wall

- Custom Corrugated Boxes

- EPE Foam Packaging

- Custom Printed Boxes

Leave a Reply